What is ERP...

The ERP is an acronym for Enterprise Resource Planning. ERP software integrates all core business functions across your entire company – including financials, sales, customer relationship management, inventory and operations. Unlike many other small business solutions on the market today, SAP Business One is a single application, eliminating the need for separate installations and complex integration of multiple modules.

ERP software includes:

● Financial management – Automate, integrate, and manage all your financial and accounting processes.

● Warehouse and production management – Manage inventory across multiple warehouses, track stock movements and manage production orders based on material requirements planning.

● Customer relationship management – Grow customer profitability and increase customer satisfaction with effective sales and opportunity management and after-sales support.

● Purchasing – Automate your entire procurement process from purchase order to vendor invoice payment.

● Reporting – Act on instant and complete information with comprehensive, real-time reports.

What can ERP achieve?

Total Visibility. ERP allows total access to every important process in your business by making data from every department easily accessible to you and your senior management.

Improved Reporting and Planning. ERP system can readily generate useful reports and analytics at any time. This software gives you the ability to analyze and compare functions across departments, without the hassle of multiple spreadsheets and emails.

Improved Efficiency. ERP can reduce the time and effort required by your workforce to carry out their daily activities which can greatly reduce or eliminate repetitive manual processes.

Standardized Business Processes. ERP allows businesses to standardize their own processes and systems, which further enhances productivity and efficiency.

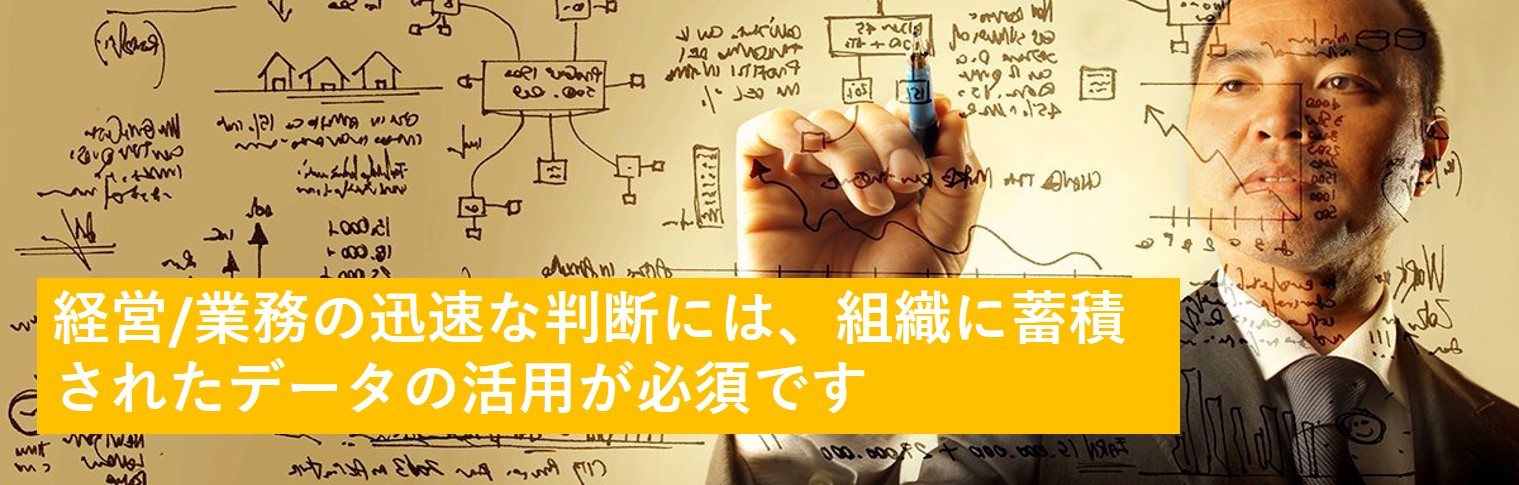

Valuating BI Solution.

New Generation of Business Intelligence.

Unblocking all the posibility in your data.

What is Business Intelligence?

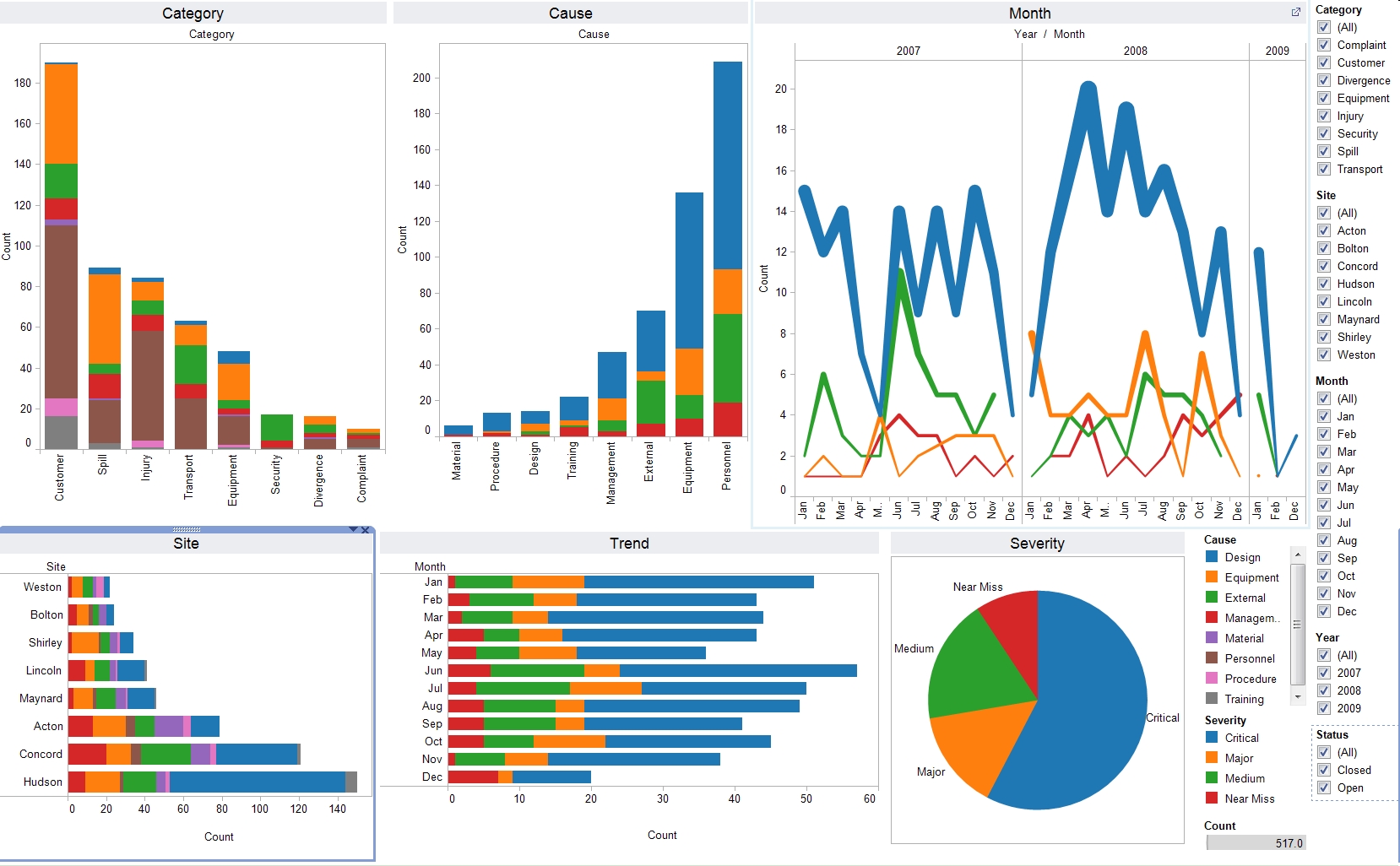

Business intelligence (BI) is a technology-driven process for analyzing data and presenting actionable information which helps executives, managers and other corporate end users make informed business decisions. BI encompasses a wide variety of tools, applications and methodologies that enable organizations to collect data from internal systems and external sources, prepare it for analysis, develop and run queries against that data and create reports, dashboards and data visualizations to make the analytical results available to corporate decision-makers, as well as operational workers.

Decision Management through BI:

- BI is a set of processes, architectures, and technologies that convert raw data into meaningful information that drives profitable business actions.

- BI systems help businesses to identify market trends and spot business problems that need to be addressed.

- BI data can include historical information stored in a data warehouse, as well as new data gathered from source systems as it is generated, enabling BI tools to support both strategic and tactical decision-making processes.

- BI system helps organization to improve visibility, productivity and fix accountability.

- BI tools perform data analysis and create reports, summaries, dashboards, maps, graphs, and charts to provide users with detailed intelligence about the nature of the business.

Advantages of Business Intelligence

Achieve high profit

Increase the profit by improving operational efficiency in their business.

Visibility improvement

BI also helps to improve the visibility of these processes and make it possible to identify any areas which need attention.

Streamlines business processes

BI takes out all complexity associated with business processes. It also automates analytics by offering predictive analysis, computer modeling, benchmarking and other methodologies.

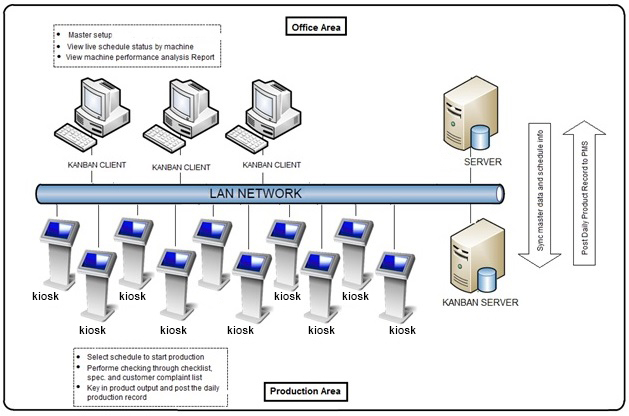

What is KANBAN...

KANBAN is a system design to capture the machine output to show real time information to production staff and management level officer to monitor the production line. The system will link up with production machine using specific design sensor to collect electronic data (Machine Output) and display as readable information using LED display counter.

What KANBAN doing...

The production is whether far ahead or behind the production during the shift by machine respectively. It will increase the transparency of production. KANBAN System is able to provide useful information for planning department to improve their planning method by compare the machine standard capacity with the actual machine output by individual schedule. There will be a Display Counter setup and install to each production machines. It is advisable to put one unit of central display (LCD or LED) unit which will install at the production area to view the output for all the machines.

Benefits of KANBAN System

- Monitor and keep track of production output achievement against target in real time at production area and office.

- Collect data output of every machine accurately either by Shift or by Part No.

- Provide efficient and user friendly production planning UI environment.

- Ability to trace the production line and machines performance.

- Provide Daily & Monthly production output analysis report.

KANBAN vs Virtualization

KANBAN System helps you to monitor production volumes and throughput from anywhere in the company. You can keep track of targets for the shift, day or month and monitor production backlog for each piece of equipment to expose bottleneck resources. It provides you with the right documentation to take action and increase production throughput.

KANBAN vs Fool Proof

Proposed KANBAN system provides the platform for user to keep useful user definable and extendable product related information such as product specification, customer complaint history and so on in PDF file format as well as checklist prepared during checklist master setup for every machine. This information will be then used as references or a guideline during production operation to avoid mistake and help on product checking.

It provides aggregate level analysis on key performance indicators sych as production, throughput, machine capacity, overall equipment effectiveness (OEE), and production cycle times. You can quickly drill down to detailed machine and production order data to perform root cause analysis, enabling you to answer questions such as:

- ● Which types of production losses contributed to overall equipment effectiveness?

- ● Which shedule and machine are underperforming?

- ● Are the production resources being utilized effectively and on target for the shift, day, week, or month?

- ● What is the cycle time trend for standard batches?

KANBAN System – A Solution That You Need

“ KANBAN System has the ability for management or production planner to retrieve production information in real time right in front of users PC or Laptop as well as at the spot of production area with the KANBAN LED Display. Current production status against achievement targets is visually present in real time to let the production operator to have self discipline by following the Plan Output to prevent behind the output schedule of achievement thus increase the productivity of every machine and reduce the delay in production. Any delay in production is able to view instantly at the System or LED Display. Moreover, it enables fast production information retrieval for analysis to fine tune the efficiency of Production. ”